Vias types according to IPC standard

Beside the PCB manufacturers recommendations and guidelines coming directly from customers the requirements concerning embodiment of the printed circuits are also contained in a series of IPC standards, in the IPC 4761 standard among others – which shortly concerns the vias protection.

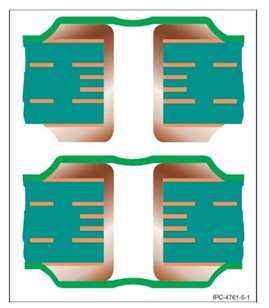

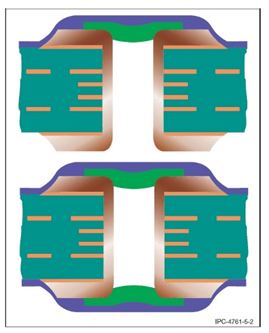

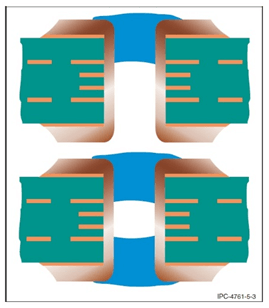

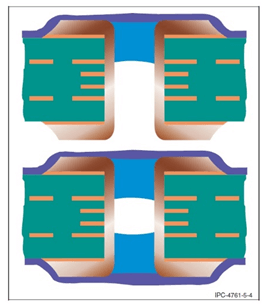

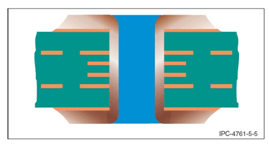

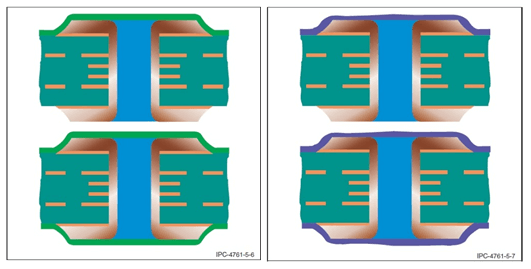

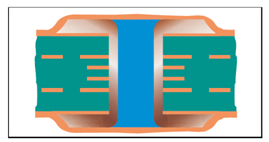

Below we present the detailed description of the types contained in the above-mentioned document and the drawings together with their cross-sections. For easier understanding the material names were designated in such way that the font colors in the description of each type correspond to the individual layers color visible on the drawings. The fact that part of the types (I – IV and VI) has two ways of embodiment was also distinguished:

- one-sided (upper drawing)

- double-sided (lower drawing).

It is also worth to add that the mask types mentioned below: dry and wet, concern only the method of applying and the material type used and not the final finish.

Type I according to IPC 4761 – vias covered with so called dry mask (green line):

Type II according to IPC 4761 – vias covered with so called dry mask (grren line) and wet mask (blue line):

Type III according to IPC 4761 – vias plugged with a dielectric material (blue line):

Type IV according to IPC 4761 – vias plugged with a dielectric material (blue line) and covered with a wet mask (velvet line):

Type V according to IPC 4761 – vias filled on the entire cross-section with a dielectric material:

Type VI according to IPC 4761 – vias filled on the entire cross-section with a dielectric material and covered with so called dry mask or wet mask:

Type VII according to IPC 4761 – vias filled on the entire cross-section with a dielectric material and then covered with the copper (so called copper plated over the top of filled holes):

Beside above-mentioned types additionally following types can be also distinguished:

- vias covered with a mask (wet) – this is a method which does not require any additional activities from the manufacturer. Holes are covered with a soldermask (according to the project or the order guidelines) and can be plugged. The biggest chance for plugging with a soldermask have holes of a diameter < 0,3 mm. It is assumed that in most of the cases the mask is just covering the holes walls and rings with a thin layer.

ATTENTION!

The mask should never be treated as an electrically isolating layer. It function is to protect the copper against the external factors influence (corrosion, soldering alloy, contaminations, etc.).

- vias filled with the copper – used in so called coolers - holes made e.g. under the microprocessor structures which task is to dissipate a big amount of heat. Other application are the high current vias.