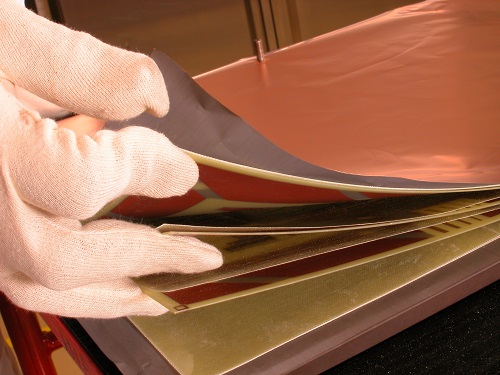

Base material of printed circuit boards: a few words about laminates

The base material used to produce the PCB affects the reliability and efficiency of the final product.

The laminate may be selected based on two criteria: quality and functionality.

Currently, printed circuits are manufactured using laminates on the following substrates: glass-reinforced epoxy (FR4), aluminium MCPCB (Metal Core PCB), Teflon, or ceramic (microwave). Usually the material is selected as per predicted working conditions and the device type. Unfortunately, the decision-making process must also include the economic factor that imposes a compromise. Keep in mind that using high-quality materials is a key factor to provide reliability and long life of the device.

The parameters that define the quality and application/functionality of the device are listed below.

Basic parameters:

- Non-conductor and copper foil thickness – mechanical resistance, fitting the case, current-carrying capacity, etc.;

- CTI class – breakdown strength between traces in wet ambient conditions;

- Fire resistance class (UL) – specifies the flammability of materials.

Temperature parameters:

- glass transition temperature (boundary): Tg – yield point;

- chemical decomposition temperature of laminates: Td – temperature causing 5% loss of laminate weight;

- delamination time: T260/288 – time after which delamination occurs (for temperatures 260 and 288°C);

- the coefficient of thermal expansion of laminates that is projected along the XY plane and the Z axis: CTEZ,XY;

- max. operating temperature (MOT) – safe temperature for continuous operation.

Humidity absorption:

- max. moisture content in laminate;

- resistance to CAF;

- Electric parameters

- dielectric constant Dk;

- lossiness Df;

- dielectric breakdown strength.