06.03.2018

Manufacture of printed circuits in harmony with the natural environment - environmental solutions

Out of concern for the natural environment in December 2002, TS PCB implemented the Integrated Quality and Environmental Management System, according to PN-EN ISO 14001 (currently in the PN-EN ISO 14001:2015 version).

The adopted environmental policy obligates the company to mini...

12.02.2018

Manufacture of printed circuits in harmony with the natural environment - recycling

One of the ways to minimise the impact on the natural environment is the reuse of materials recovered from waste accompanying PCB manufacture. This technique reduces the final amount of waste and the use of natural resources. A list of the main waste groups (or their components), together with the p...

24.01.2018

Manufacture of printed circuits in harmony with the natural environment - legal requirements

The generation, storage and disposal of waste at TS PCB is mainly regulated by the waste generation permit.

It contains a brief description of the manufacturing technology (type and parameters of the plants that are the source of waste generation), and defines the types and acceptable...

16.01.2018

Manufacture of printed circuits in harmony with the natural environment - waste classification, storage and disposal

The manufacture of printed circuits is a very complex process that uses a wide range of materials and chemicals. Many of them require special storage and the use of specialised methods of industrial waste disposal. Some of the substances are dangerous for humans and the environment. The article disc...

30.11.2017

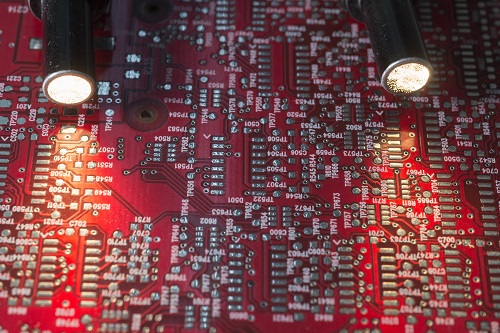

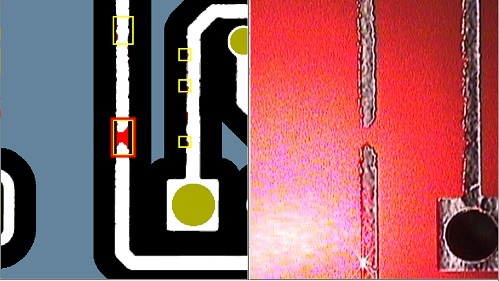

Testing printed circuits: AOI optical testing

The basic task of electrical testing is to verify the conformity of the design’s mosaic network, reproduced in a real, manufactured circuit. This enables the detection of critical damage to the mosaics in the form of short and open circuits that modify the network structure. In the case of opt...

23.11.2017

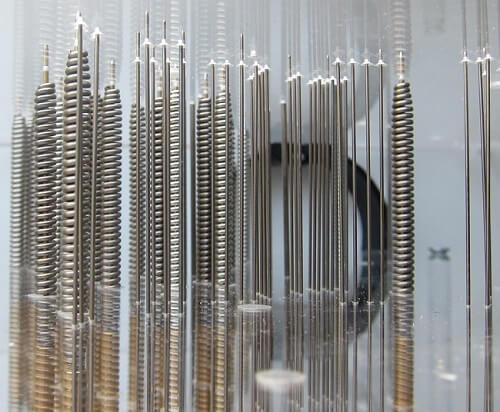

Testing printed circuits: Blade testers

In contrast to testers with moving probes which have a small number of measuring heads (usually 4), in the blade testers a significant number of fixed measuring probes are used in the form of needles of different diameters (fig.1). The diameters of the needles match the contact surface area of the t...

08.11.2017

Testing printed circuits: Finger testing – testing time optimization

Although application of the fast mechanics and the measuring heads relocation improvement which guarantees testing even a few thousand test points per minute the test time of the single production format containing complicated and packed HDI circuits may reach a few minutes or even longer. Long test...

03.11.2017

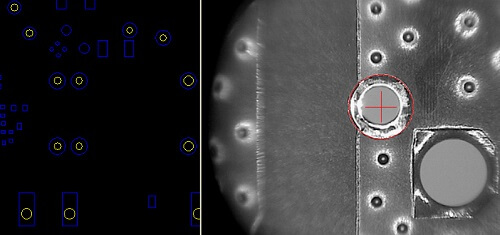

Testing printed circuits: Electrical testing – testers with moving probes

The operation rule of those type testers, also called finger ones, relays on performing measurements with use of measuring heads equipped in probes moving on both sides of the stationary fixed printed circuit (pic. 1a). In the most popular configuration the tester is disposing four resistance measur...

27.10.2017

Testing printed circuits: Classification of the circuits testing methods and introduction to electrical testing

Printed circuits production similar to a serial production of other goods is characterized with a certain efficiency level or the level of the rejected pieces. Rejected circuit means each piece which is not fulfilling design assumptions of the customer or precisely specified industry standards. An e...

13.06.2017

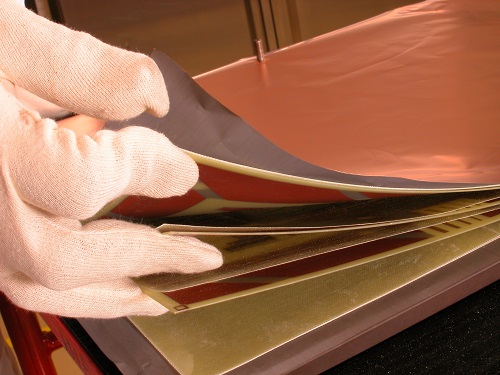

Base material of printed circuit boards: a few words about laminates

The base material used to produce the PCB affects the reliability and efficiency of the final product.

The laminate may be selected based on two criteria: quality and functionality.

Currently, printed circuits are manufactured using laminates on the following substrates: glass-rein...

05.04.2017

Certificate ISO 9001:2015 and 14001:2015

The Integrated Quality and Environmental Management directly corresponds with the quality of the PCB. Therefore we are glad to gain new ISO certificate for norm 9001:2015 i 14001:2015.

17.11.2016

IPC circuit classes

According to the IPC-A-600 document, there are three general classes of final products. The purpose of this classification was to identify the following differences:

manufacture process

technological advancement

operational reliability requirements depending on the board purpose.

In...

10.11.2016

What technical standards should the PCB comply with?

The most common specifications used within the printed circuit boards production are the documents issued by the IPC. The main set: IPC-6010 “Family of Board Performance Documents" includes the following specifications:

6011: Generic Performance Specification for Printed Boards,...

25.11.2015

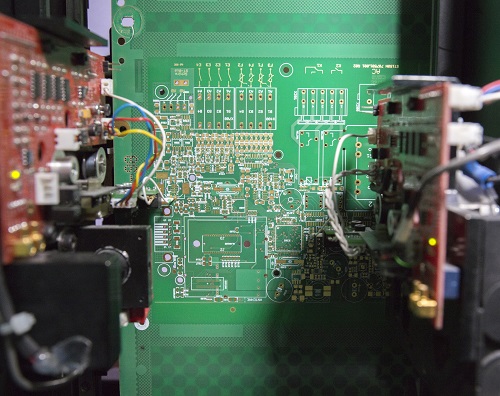

Structure, characteristics and design of multilayer printed circuit boards

Modern electronic devices are expected to deliver high functionality, small form factors and high reliability. These features are achieved with large numbers of miniature and composite integrated circuits which are interconnected by complex networks. Mapping those IC's on a typical double-side...

25.11.2015

Impact of laminate parameters on the life and performance of printed circuit boards

The life (or durability) and reliability of electronic equipment depends on the quality and types of applied components, including the printed circuit boards (PCBs), which are the cornerstone of a performer electronic circuit. Hence it is extremely important to properly select the parameters of ba...

25.11.2015

Prime factors of printed circuit board quality and durability

It is difficult to imagine a modern electronic device that lacks a PCB. The continuing development of technologies and fierce market competition force electronic equipment manufacturers to improve product functionality and appeal by adopting the state of the art solutions. This usually requires pa...

25.11.2015

Quality of printed circuit boards. Basic principles of evaluation

The current requirements and expectations of customers in the PCB sector for reliable and failure-free performance of purchased equipment are definitely higher than only a few years ago. An undisputed reason is the dynamic growth of technology with the concomitant progress in quality. Even the sim...

25.11.2015

PCB quality depends on designers

The quality of printed circuit boards (PCBs) relies heavily on the design method. It is the stage at which the designers already define the production workflow and the probability of quality defects. Many potential errors can be avoided by introducing cosmetic changes to the design, which will pro...

25.11.2015

Advanced technologies of printed circuit boards

The complexity of electronic circuits has been growing, and the emerging new technologies raise the bar for these products. The parameters of PCBs (printed circuit boards), which are components of electronic equipment, must also follow the demands. Hence PCB designers should be aware what solution...

25.11.2015

Aluminium core PCBs: parameters, applications and design

Rosnąca stale złożoność układów oraz stopień upakowania ich elementów na obwodach drukowanych zaczyna przysparzać konstruktorom i inżynierom problemów związanych z zapewnieniem właściwego odprowadzania ciepła, wydzielanego w półprzewodnikowych elementach wys...

.jpg)

.JPG)