Testing printed circuits: Finger testing – testing time optimization

Although application of the fast mechanics and the measuring heads relocation improvement which guarantees testing even a few thousand test points per minute the test time of the single production format containing complicated and packed HDI circuits may reach a few minutes or even longer. Long test time becomes the major restriction of the finger testers and in case of a small dimensions circuits which can be in a single format in a few hundred pieces amount. To reduce the testing time many producers propose their own, proprietary, optimization equipment and software solutions. Exemplary optimization technics will be discussed basing on Gardien company solutions – global supplier of the equipment and technological solutions in printed circuits testing domain.

One of the method of reducing the testing time is using the preliminary capacity test, preceding the resistance test. It relays on calculating electrical net capacities basing on the design and comparing them in all real circuits present in the production format. About possibility of using the capacity test and the net choice decides the software which is analyzing the mosaics distribution in the examined circuit. The basic criterium of applying the capacity test is presence in mosaics of reference areas with big copper content in relation to which it is possible to specify the net capacities located on the rest of the layers. Basic advantage of this test is significant shortening of the measuring procedure, because one or two probes are constantly touching test points of the reference net layer and the rest of the probes are examining capacity of the rest of nets with use of a single probe touch. In case of detecting significant deviation of the net capacity in one of the circuits on the production format the automatic switching of the testing mode to the resistance test occurs in order to precisely verify the net of this circuit.

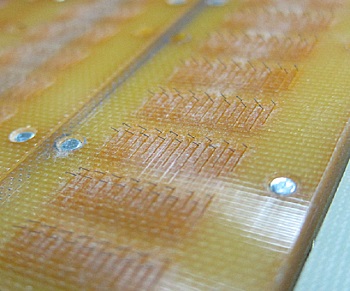

Other interesting concept was used in the Acceler8 tester from Gardien company (pic. 1a) used in TS PCB. It relays on making preliminary coarse test in a special tester in which the measuring head consists of the 4096 probes arrangement and is made in a form of a carpet from delicate copper hairs distributed with stationary raster (pic. 1b).

(a)

(b)

Pic. 1. Acceler8 (a) tester and view of one of its module of it measuring head equipped in probes (b).

Before commencing the test, it is necessary to fully test a single production format on a finger tester in order to collect the learning data vector for Acceler8 basing on which the software determines which head probes can be used with consideration of test points on the format. Then the next formats are directed already onto the Acceler8 tester where during the measuring procedure they are swiped with probes hairs from one, and after reposition, from the other side. Basing on the collected data the continuity and isolation test results are established. For each format the software is analyzing measurements results and specifies how many percent of the net was tested and generates reduced supplementary test program for the rest of the nets for the finger tester.

Depending on mosaics arrangement you achieve this way total test time shortening from 30% up to over 50%. Due to an extended learning process of Acceler8 tester the test time gain is visible already from a few production formats.

The test time offered by finger testers is acceptable mainly in the prototype and low series production. Such use is favorable also thanks to a low commissioning cost, because preparing the test procedure takes place only in the program domain by preparing the program for testing and does not require additional equipment investments.