PCB elements: HOLES TYPES

Due a big variety of functions and applications of printed circuits the different types of the holes can be present in their structure. They can be classified in a general way – metalized / non-metalized or because of their shape or function etc.

The classification considering most types of holes types used in printed circuits is presented below.

Basic classification:

- vias/metalized holes

- standard – diameter from 0.2 mm

- micro-vias – diameter below 0.2 mm (typical: 0.1 mm; 0.15 mm)

- non-metalized holes: diameter from 0.25 mm

- without annular ring

- with the annular ring moved from the hole edge

- with the annular ring up to the hole edge.

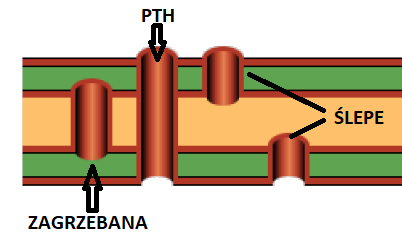

Classification by what layers they pass through / what layers they connect:

- PTH/NPTH – they pass through the entire thickness of the PCB;

- blind/backdrilling – vias/holes drilled to the depth (visible from outside but only on one side of the PCB);

- buried vias – vias connecting the internal layers (not visible from outside).

Classification by a finishing method:

- not covered by a soldermask – without cover or covered with the protection layer e.g. HAL, ENIG etc.

- covered with a soldermask (usually not plugged)

- filled (copper, dielectric)

- filled and covered with a soldermask (standard)

- filled and covered with a soldermask (flat, bigger degree of filling).

Non-typical:

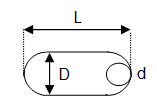

- slotholes:

- special case: slotholes 2D - the slothole length (L) is smaller or equal double it width (2D)

L ≤ 2*D sinkholes (beveled).

L ≤ 2*D sinkholes (beveled).

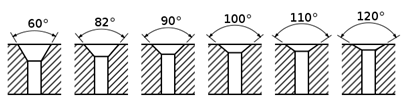

- sinkholes (beveled)

Classification by the diameter tolerance (examples):

- standard, typically: + 0.1 mm / - 0.05 mm

- pressfit: e.g. + 0.05 mm / - 0.05 mm.

The parameters and application of individual types of holes will be presented in the forthcoming articles.