Bridges – structure and parameters

If PCBs are made in panels and scoring cannot be performed, PCBs are held using so called bridges.

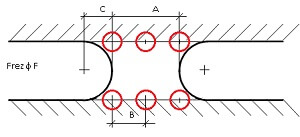

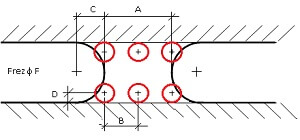

If the order does not specify their parameters, perforated bridges are normally installed. Keep in mind that the minimum distance of traces, pads, or compound from the perforation hole edges must be at least 10 mils. Select appropriate type in accordance with Fig. 1 or Fig. 2, ensuring that the minimum distance is maintained.

Fig. 1. Standard perforated bridge used when no pads or traces are present close to the PCB edge (≥10 mils from the edge).

Fig. 2. Standard perforated bridge used when pads or traces are present at the PCB edge (<10 mils from the edge).

Parameters indicated in figures above are defined in the table below:

|

F

(milling diameter)

|

A

|

B

|

C

|

D

|

|

2.0

|

2.0

|

1.0

|

1.0

|

0.35

|

|

1.5

|

1.8

|

0.9

|

0.75

|

0.30

|

|

1.0

|

1.0

|

0.5

|

0.50

|

0.20

|

Standard guidelines for the use and distribution of bridges are as follows:

- bridges are perforated unless the order specifies otherwise;

- one bridge should be installed per every 50 mm section of the PCB (side);

- other bridges can be used conditionally if, for example, it is required due to the shape/size of the PCB (such as no perforation, unusual distribution, additional bridges).